Synergex™ Sanitizer and Disinfectant

Synergex™ Sanitizer and Disinfectant is an EPA-registered* mixed peracetic acid (PAA) based sanitizer and disinfectant that helps food and beverage manufacturers enhance food safety, quality assurance, worker safety and air quality. Synergex Sanitizer and Disinfectant has been developed to kill 99.9999% of Pseudomonas aeruginosa and Listeria monocytogenes pathogens in biofilms on hard, non-porous food contact surfaces, at no-rinse concentration level options. Synergex is listed on the EPA’s List N for use against SARS-CoV-2**, the virus that causes COVID-19.

*U.S. EPA Reg. No. 1677-250

**Synergex has demonstrated effectiveness against viruses similar to SARS-CoV-2 on hard, non-porous surfaces. Therefore, Synergex can be used against SARS-CoV-2 when used in accordance with the directions for use against Reovirus on hard, non-porous surfaces. Refer to the CDC website at cdc.gov/coronavirus for additional information.

Synergex™

Program Overview

Synergex is a sanitizer and disinfectant designed for food and beverage processing plants. Our patented formulation helps reduce day-to-day variability and promotes quality assurance. A powerful antimicrobial agent helps protect against many pathogens and spoilage organisms as well as bacteriophage, broad yeast and mold. Effective on virtually all surfaces and in clean-in-place (CIP) applications, Synergex helps food and beverage manufacturers enhance food safety while improving productivity.

Learn more about how Synergex can optimize your food and beverage operations through increased productivity, improved worker safety and air quality, and minimize environmental impact.

The Synergex Advantage

Effective on virtually all surfaces and with CIP applications, Synergex can help improve product quality and maximize efficiency.

Application Areas

- Surfaces in general (no contact with food)

- Food contact surfaces

- Food transporters/conveyors

- Vacuum sealed packaging

- Non-porous hand gloves

- Non-food contact packaging equipment

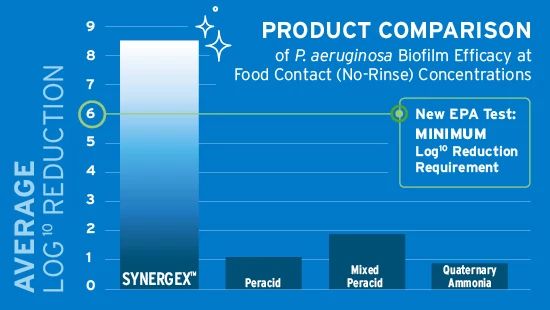

Synergex™ Earns EPA Biofilm Claim for Food Contact Surfaces

A biofilm kill claim for food contact surfaces was desperately needed. With no approved test method available, Ecolab partnered with the EPA to develop a food contact surface biofilm test method. Learn more about the development of the test, and how Synergex measures up.

Synergex™: A First Line of Defense Against Biofilms

Synergex is the only no-rinse sanitizer and disinfectant to hold an EPA claim of penetrating and killing biofilms on food-contact surfaces – helping you measurably improve your food safety and product quality metrics. Biofilms on food-contact surfaces in the food and beverage industry have been a longstanding issue, until now. So solve this problem, Ecolab partnered with the EPA to develop the first-ever food-contact biofilm test method.

Synergex™ Success Stories

Synergex has helped a wide variety of food and beverage manufacturers improve their product quality, promote food safety and increase productivity.

Cheese and Whey Processing

Achieve plant goals. The plant was able to move from a six-step CIP program to a four-step program on the cheddar master, salter, Vat 8, milk and curd line, rennet line, vat chase and block foamers allowing the plant to gain two additional vats of cheese per day.

Fluid Dairy

Cheese Processing

Carbonated Beverages