Boiler Water Treatment

Process Condensate Control

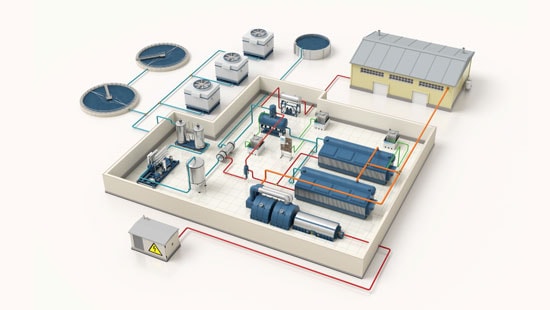

Process condensate contaminated with “sugar shots” can become dangerous when reused in boiler and cooling system. 3D TRASAR for Sugar is able to detect “sugar shots” in real time and divert contaminated condensate, preventing from causing boiler corrosion or rapid biological fouling in cooling tower.

Our Boiler Water Treatment Approach

Nalco Water has helped thousands of customers globally with their boiler systems through automation, service, specialty chemistries, and equipment, to drive overall reduction of total cost of operation. We focus on customers in institutional, manufacturing, food & beverage, power generation, chemical, primary metals, paper, and mining. Our experience with firetube and water tube boilers optimization has led to millions of gallons in water savings and asset protection.

Benefits to Using Our Boiler Water Treatment Program:

- Safe reliable steam that avoids disruption to your production

- Water and energy savings that directly minimize your total cost of operation

- Extends asset life to avoid costly down time and unplanned capital expenditures

- Real-time system knowledge with instantaneous response to reduce maintenance and increases labor efficiency

Boiler Water Chemicals, Programs, Products, Equipment and Services

Explore our treatment offerings related to boiler and boiler chemical treatment management and maintenance.

We couldn't find any results for "".

Nalco Water HandBook

This industry-standard resource offers practical guidance on the use and treatment of water and wastewater in industrial and institutional facilities. Revised to align with the latest regulations and technologies, The Nalco Water Handbook, Fourth Edition, explains water management fundamentals and clearly shows how to improve water quality, minimize usage, and optimize treatment processes. Throughout, new emphasis is placed on today’s prevailing issues, including water scarcity, stressors, and business risk.

Covers all essential water treatment topics, including:

- Water management fundamentals

- The business case for managing water

- Water sources, stressors, and quality

- Basic water chemistry

- Impurity removal

- Steam generation

- Cooling water systems

- Safety for building water systems

- Post-treatment

- Energy in water systems

- Water applications across various industries

Watch the video to learn more and purchase the book by clicking the link below!